PRODUCT DESCRIPTION

The Roto-Joint is a specialized joint created by UMI Performance to replace spherical rod ends on control arms for various GM vehicles. It can be installed in control arms that use a ¾”-16 left-hand threaded rod end. Installation is straightforward: simply remove the existing rod end and screw in the Roto-Joint assembly. This joint is perfect for replacing worn rod ends that are causing noise.

The Roto-Joint comes fully assembled with a grease fitting, a new jam nut, and a clear zinc finish. It features CNC machined threads made from 4140 Chrome Moly steel, DOM tubing, and is TIG welded for enhanced strength and durability. The Spanner Wrench is essential for adjusting and disassembling Roto-Joints in UMI Performance products. It helps tighten the adjusting ring to apply more pressure to the delrin inside the Roto-Joint, which prevents wear over time. Additionally, the wrench can be used to disassemble the Roto-Joint for cleaning, inspection, and rebuilding.

UMI's Roto-Joint allows for 28 degrees of total rotation and unrestricted movement in vehicle suspensions. It blends the characteristics of a spherical rod end with the comfort of a softer bushing. This design prevents suspension bind, improves traction, and reduces wheel hop. The Roto-Joint features a 4140 chrome moly, hard chrome plated spherical ball that rotates within a delrin race. The delrin material offers high wear resistance, excellent tensile strength, and maintains its properties effectively. The housing is constructed from 4140 chrome moly threads, with a CNC machined bushing holder that is TIG welded for durability. The Roto-Joint is adjustable and 100% rebuildable, making maintenance and replacement of worn parts easy.

PRODUCT FEATURES

- Replaces spherical rod ends on UMI Performance control arms for specific GM vehicles

- Works with other brand control arms for listed vehicles using ¾”-16 left hand threaded rod end

- Easy replacement for worn out rod ends or noisy rod ends

- Supplied fully assembled with grease fitting, jam nut, and clear zinc finish

- Bushing width of 2.400” with 3/4”-16 left hand threads and 2.000” of thread adjustment

- Accepts both ½” and 12mm bolts

- CNC machined threads from 4140 Chrome Moly steel

- DOM tubing and TIG welded for strength and durability

- Spanner wrench used for adjusting and disassembling Roto-Joints

- Allows 28 degrees of total rotation for unrestricted movement in suspension

- Designed to work like a spherical rod end but with streetable qualities of a softer bushing

- Prevents suspension bind, improves traction, reduces wheel hop

- Features 4140 chrome moly, hard chrome plated spherical ball rotating in delrin race

- Delrin bushing material chosen for wear resistance, tensile strength, and consistency

- Housing features 4140 chrome moly threads and CNC machined bushing holder TIG welded for strength

- Adjustable and 100% rebuildable for longevity and maintenance

This Product Features

Designed & Manufactured in the USA

North American Raw Materials

Precision Welds

| Manufacturer |

|---|

UMI Performance

21 Years In The Industry

North American Raw Materials

Proudly partnering with leading USA steel suppliers, we source the finest North American mined and milled steel

Precision Bent DOM Tubing

Machine-guided DOM tubing bends maintain correct geometry while maintaining material strength.

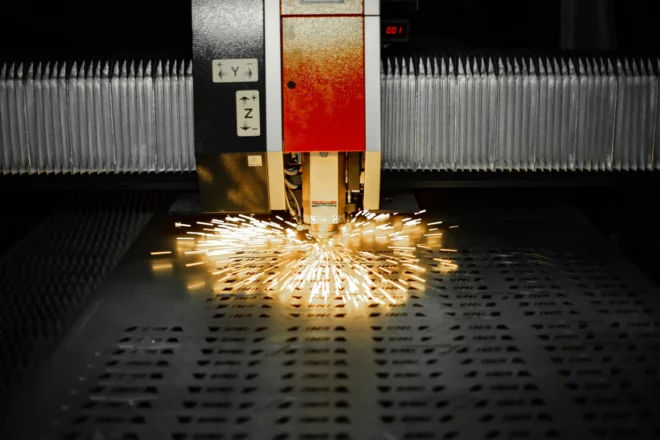

Laser Cut Plating

We take North-American sourced plating and precision-cut each component with the latest laser-cutting technology.

Durable Powder Coating

Each finished part is properly prepped and coated with high quality Tiger Dry Lac powder coat, providing a tough long-lasting finish.

Consistent Welds

Our highly-skilled welders and robotic-welders provide consistent welds and ultimate part penetration.

100% USA Made

We take pride in providing 100% USA-Manufactured suspension components.

Components

Manufacturing

Welds

Shipping Guidelines

Flat Rate Shipping ($12.95) is only offered on Retail orders over $149 shipped via Ground in the Continental United States.

All International customers are responsible for any applicable duties and/or taxes incurred on your shipment upon delivery.

Return Information

All returns are subject to the authorization of UMI Performance, Inc. Please email [email protected] for a Returned Merchandise Authorization (RMA) number. Our Sales team will either authorize or deny the request for return at its discretion. Any product returned without an issued RMA number will not be credited. All returns must be made within 30 days of delivery, be in new condition, be in original sealed packaging and include the RMA number on the outside of the packaging. No exceptions. All products and their packaging must be in new and unopened condition. Products that have been altered, installed, or modified are not returnable. All shipping costs for returns are the responsibility of the customer. All returns are subject to a 20% restocking fee as well as the original shipping charges that UMI Performance may have incurred while shipping your order.

Due to the majority of Viking products being drop shipped, we can not offer returns on any Viking products. If you purchase a Viking product be sure it fits your application. If you need technical assistance prior to placing order please contact [email protected]

RELATED PRODUCTS

In stock

In stock

In stock

In stock

In stock