$529.99 – $729.99

PRODUCT DESCRIPTION

Our tunnel-mounted torque arm, UMI P/N 2200, is a powerful upgrade for your street/strip vehicle. This torque arm replaces the factory arm with a more rigid design that improves instant center, reduces response time, and enhances launch performance. By relocating the torque arm to the tunnel area, it protects your transmission from damage and prevents cracked tail housings. The adjustable arm allows for easy optimization of pinion angle and instant center location, while the greaseable polyurethane bushings reduce road noise. The bolt-on design requires no welding or drilling for installation and includes a double shear bracket for an optional bolt-on drive shaft loop (UMI P/N 2204).

Manufactured from 1-1/4” USA DOM seamless steel tubing, the torque arm is both tough and reliable. The crossmember features heavy-duty USA rectangular tubing, and the rear mount is made from 3/8” thick mild steel to fit various axle housings. Finished with durable UMI red or gloss black powder coat, the torque arm is designed, tested, and raced in Philipsburg, PA, USA. For vehicles with factory exhaust systems or shorty headers, P/N 2200 provides adequate exhaust clearance. A rear torque arm hardware kit (UMI P/N 3003 or P/N 2998 for Moser Engineering 12-Bolt) may be required for proper installation. For even greater strength and weight savings, consider upgrading to the CrMo version with 4130 CrMo tubing.

Our instructional video offers guidance on setting the pinion angle in a professional tone. Upgrade to the UMI tunnel-mounted torque arm and enjoy improved performance on the street and at the strip.

PRODUCT FEATURES

- Protects transmission from damage by relocating torque arm to tunnel area

- Reduces wheel hop and solves traction problems

- Allows for easy on-car pinion angle and instant center adjustments

- Greaseable polyurethane bushings keep road noise to a minimum

- Bolt-on design requires no welding or drilling during installation

- Includes drive shaft loop mount for adding optional drive shaft loop

- Fabricated from 1-1/4” USA DOM seamless steel tubing

- Crossmember uses heavy duty USA rectangular tubing

- Made with 4140 CrMo tube adapters and adjuster

- Strong 3/8” thick mild steel rear mount fits various axle housings

- Durable UMI red or gloss black powder coat

- Manufactured, tested, and raced in Phillipsburg, PA, USA.

This Product Features

Designed & Manufactured in the USA

Durable Powder-Coat

North American Raw Materials

Precision Laser Cut Components

Precision Welds

| Material |

Chromoly ,Mild Steel |

|---|---|

| Fitment | |

| Platform | |

| Manufacturer | |

| Finish |

Powder Coat |

| UOM |

Each |

| Direct Bolt-On |

Yes |

| Modifications |

None |

| Hardware |

Included |

UMI Performance

21 Years In The Industry

North American Raw Materials

Proudly partnering with leading USA steel suppliers, we source the finest North American mined and milled steel

Precision Bent DOM Tubing

Machine-guided DOM tubing bends maintain correct geometry while maintaining material strength.

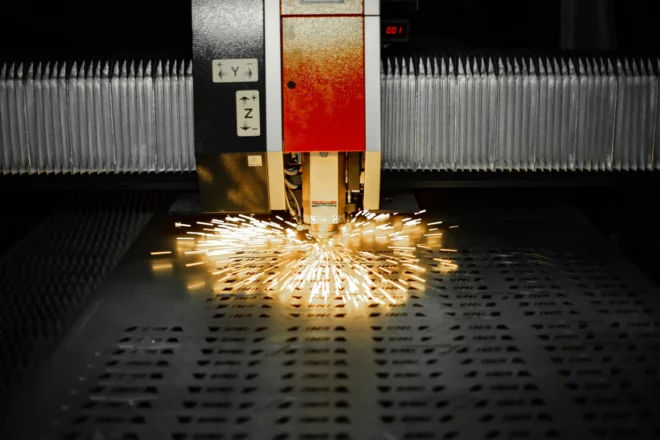

Laser Cut Plating

We take North-American sourced plating and precision-cut each component with the latest laser-cutting technology.

Durable Powder Coating

Each finished part is properly prepped and coated with high quality Tiger Dry Lac powder coat, providing a tough long-lasting finish.

Consistent Welds

Our highly-skilled welders and robotic-welders provide consistent welds and ultimate part penetration.

100% USA Made

We take pride in providing 100% USA-Manufactured suspension components.

Components

Manufacturing

Welds

Shipping Guidelines

Flat Rate Shipping ($12.95) is only offered on Retail orders over $149 shipped via Ground in the Continental United States.

All International customers are responsible for any applicable duties and/or taxes incurred on your shipment upon delivery.

Return Information

All returns are subject to the authorization of UMI Performance, Inc. Please email [email protected] for a Returned Merchandise Authorization (RMA) number. Our Sales team will either authorize or deny the request for return at its discretion. Any product returned without an issued RMA number will not be credited. All returns must be made within 30 days of delivery, be in new condition, be in original sealed packaging and include the RMA number on the outside of the packaging. No exceptions. All products and their packaging must be in new and unopened condition. Products that have been altered, installed, or modified are not returnable. All shipping costs for returns are the responsibility of the customer. All returns are subject to a 20% restocking fee as well as the original shipping charges that UMI Performance may have incurred while shipping your order.

Due to the majority of Viking products being drop shipped, we can not offer returns on any Viking products. If you purchase a Viking product be sure it fits your application. If you need technical assistance prior to placing order please contact [email protected]

This '2200 - 1993-2002 GM F-Body Tunnel Mounted Torque Arm, Stock Exhaust, Kooks LT's' fits the following platforms:

1993-2002 GM F-Body

- 1993-2002 Chevrolet Camaro

- 1993-2002 Pontiac Firebird

This 2200 - 1993-2002 GM F-Body Tunnel Mounted Torque Arm, Stock Exhaust, Kooks LT's fits the following vehicles:

Chevrolet

Camaro

- 1993 Chevrolet Camaro

- 1994 Chevrolet Camaro

- 1995 Chevrolet Camaro

- 1996 Chevrolet Camaro

- 1997 Chevrolet Camaro

- 1998 Chevrolet Camaro

- 1999 Chevrolet Camaro

- 2000 Chevrolet Camaro

- 2001 Chevrolet Camaro

- 2002 Chevrolet Camaro

Pontiac

Firebird

- 1993 Pontiac Firebird

- 1994 Pontiac Firebird

- 1995 Pontiac Firebird

- 1996 Pontiac Firebird

- 1997 Pontiac Firebird

- 1998 Pontiac Firebird

- 1999 Pontiac Firebird

- 2000 Pontiac Firebird

- 2001 Pontiac Firebird

- 2002 Pontiac Firebird

RELATED PRODUCTS

In stock

In stock

Out of stock

In stock

Out of stock